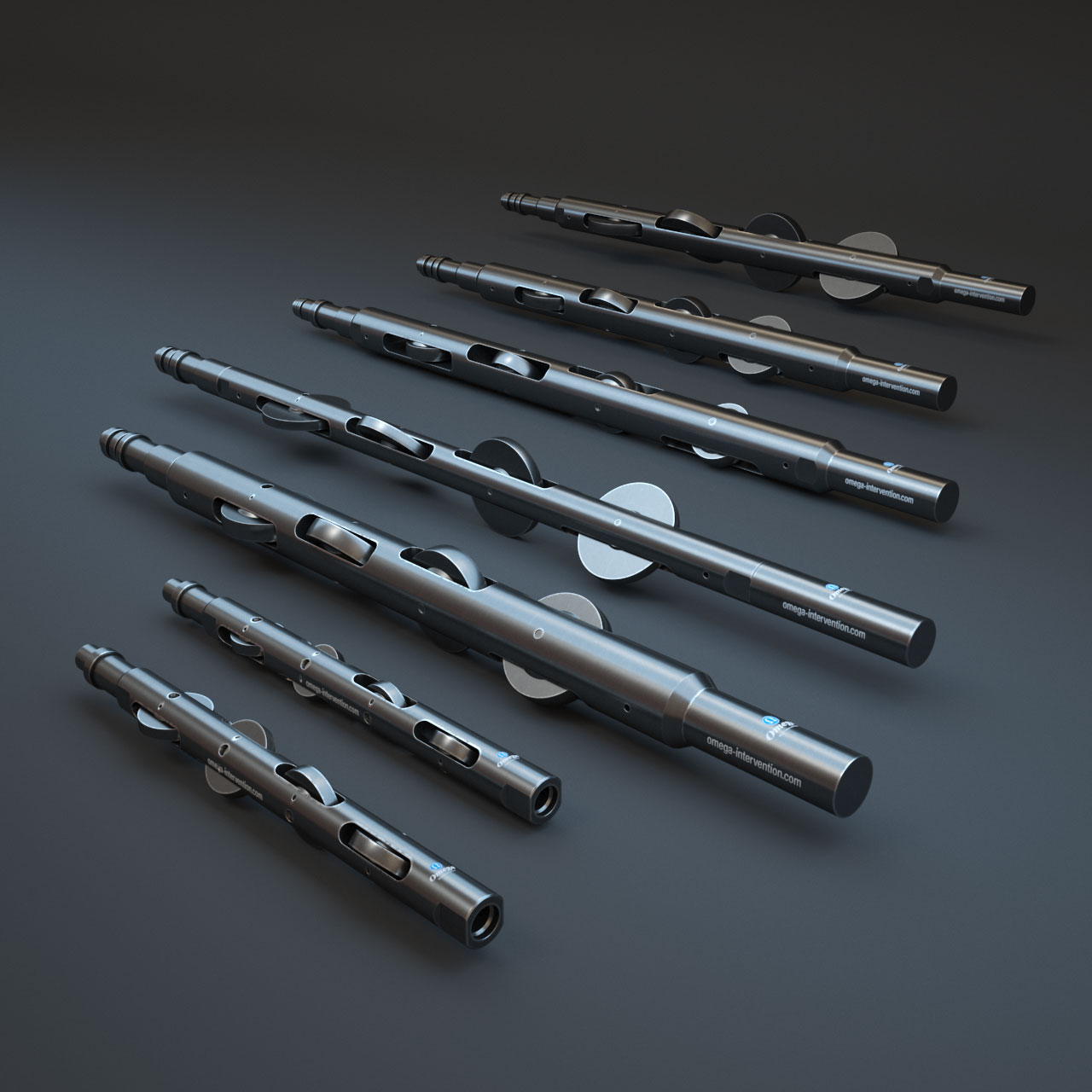

Slickline Roller Sub

Wireline Products

Slickline Roller Sub

The Omega Roller Sub was designed to fill a need in the rolling systems market for a simple and reliable means of reducing toolstring friction in order to allow deeper penetration into deviated wellbores and also to enhance our slickline tractor and catapult operations.

The O.R.S. system features interchangeable hardened wheels that allow the fitment of the largest wheel size possible for a particular completion. The large diameter wheel has two positive benefits. It lifts the tool string clear of any foreign bodies, scale or debris in the tubing preventing the tools between the rollers from “bellying out” on the tubing wall. The large radius also allows easier passage over obstructions where smaller wheel sizes would encounter difficulty.

Each wheel features three bearings, two thrust and one double angular. The wheels are rigidly mounted on a threaded shaft that is double locked to the main body. The roller sub features four wheels per roller in a spiral, which guarantees two contact points with the tubing at any one time.

In addition to reducing the effects of downhole friction on the tool string, the Omega triple bearing system also acts to mitigate mechanical damage to tubing string that may be otherwise caused by repeated reciprocation of the wireline conveyed tool string against the I.D. of the tubing string.

A roller sub for electric line operations is available which incorporates a monoconductor type 44 cable protected by stainless steel tubing which is recessed into the sub body. Metal to metal seals on the tubing connections give a 10,000 p.s.i. rating for the sub.

FEATURES

- Interchangeable hardened wheels.

- Thrust & angular bearings fitted throughout.

- Two contact points guaranteed with tubing at any one time.

- Extremely robust design.

- 360° wheel coverage.

APPLICATIONS

- Friction reduction in deviated well bores.

- Centralisation of downhole devices.

BENEFITS

- Enhances jar impact.

- Enables use of wireline in high deviation wells.

- Provides “tool lift”.

- Highly debris tolerant.