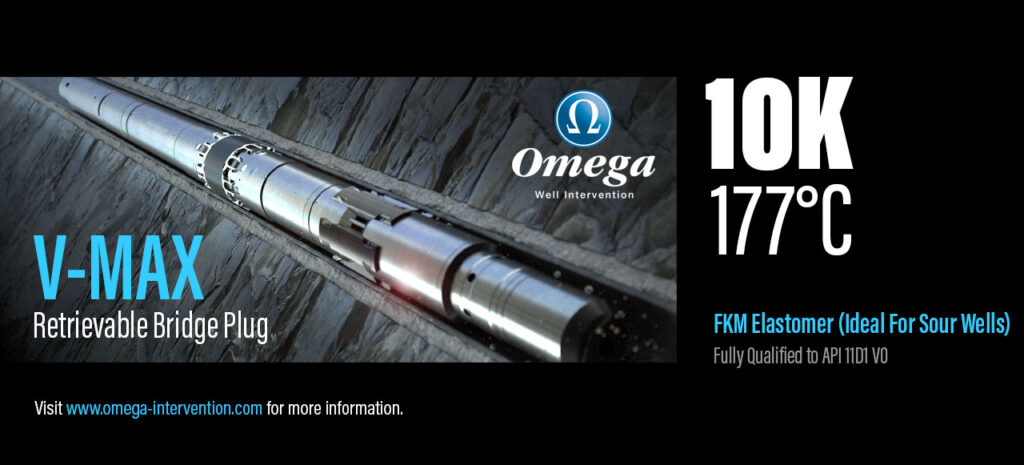

New 7″ V-MAX Retrievable Bridge Plug Now Available. 10,000psi 177°C

We were excited to announce that our new V-Max Retrievable Bridge Plug is now available. Visit the V-MAX product page for more information https://omega-intervention.com/v-max-retrievable-bridge-plugs/